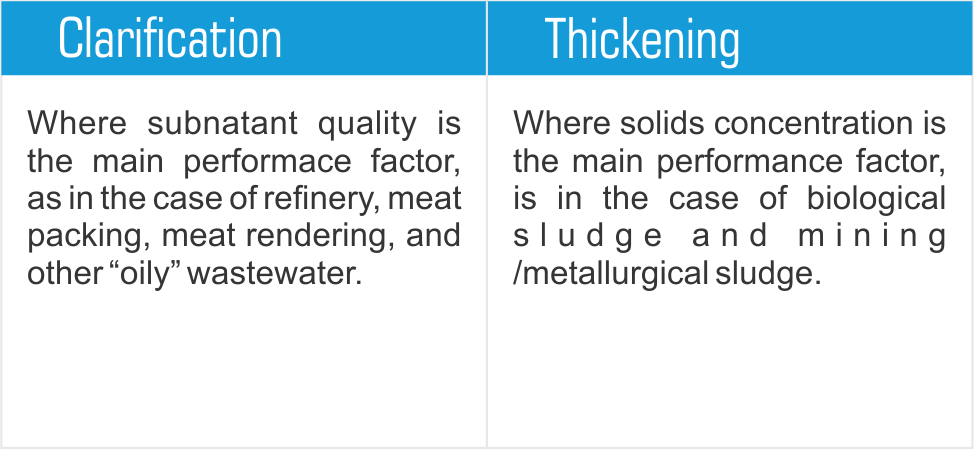

Dissolved air flotation (DAF) unit provides effective removal of suspended solids, fats, oils and greases from liquids by separated the particles from water using floated air bubble. Dissolved air flotation in solid-liquid separation is implemented through the introduction of micron-sized gas (usually air) bubbles into the liquid phase. As the micro bubbles attacks to the solids, the resultant buoyant force of the combined solid-gas causes the matrix to rise to the surface where it is collected. An important principle of the system is the introduction of air (or other gas) into the recirculated effluent, and blending the recirculated flow with the influent flow. The two major application of DAF unit are clarification, where subnatant quality is the main performance and thickening where solids concentration is the main performance factor. The extension of this application, DAF unit could be applied in Algae removal, textile, snack foods, poultry processing, oil refinery and municipal wastewater.

CPI (Corrugated Plate Interceptor) Separator

The Liqua CPI Separator design determined by calculating the relationships between the flow-rate, oil and water specific gravity, temperature and oil content. In CPI separator, the paralel plates are corrugated (like roofing material) with the axis of the corrugations parallel to the direction of flow. The plate pack is inclined at an angle of 45° and the bulk water flow. The oil sheet rises upward counter to the end of the plate pack, it is collected in a channel and brought to the oil-water interface.

In areas where sand or sediment production is anticipated, the sand should be removed prior to flowing through a standard CPI. Because of the required laminar flow regime all plate coalescers are efficient sand setting devices. Experience has shown that oil wet sand may adhere to a 45° slope. Therefore, there is the possibly that the sand will adhere to and clog the plates. In addition, the sand channels installed at the end of the plate pack cause turbulence that affects the treating process and are themeselves subject to sand plugging. To eliminate the above problems, an “upflow” CPI unit employing corrugated plates with a 60° angle of inclination may be used.

DAF (Disolve Air Flotation) Separator

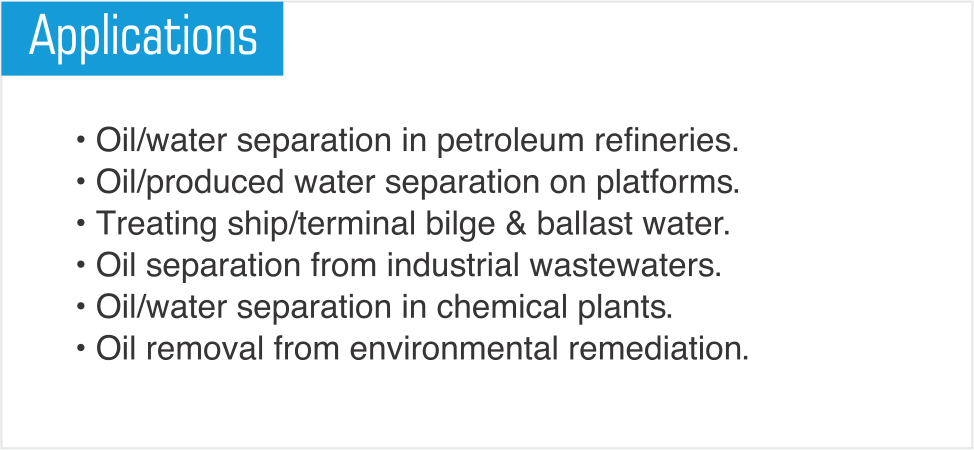

Liqua DAF separator provides effective removal of suspended solids, fats, oils and greases from liquids by dissolved air flotation. Dissolved air flotation in solids-liquid separation is implemented through the introduction of micron-sized gas (usually air) bubbles into the liquid phase. As the micro bubbles attach to the solids, the resultant bouyant force of combined solid-gas causes the matrix to rise to the surface where it is collected. An important principles= of the system is the introduction of air (or the gas) into the recirculated effluent, and blending the recirculated flow with the influent flow. The recycled effluent is pumped to a pressurized air sturation tank where the maximum possible quantity of air (gas) is dissolved in the recycle stream. The recycle stream is the blended with the influent flow prior to entering the flotation chamber. As the air (gas) saturated flow is restored to atmospheric pressure, microscopic bubbles are formed. When the recycle stream enters the tank, baffles assure thorough, rapid blending with the raw influent flow and dispersion throughtout the cross section of the tank.

DAF Application

Typical Application