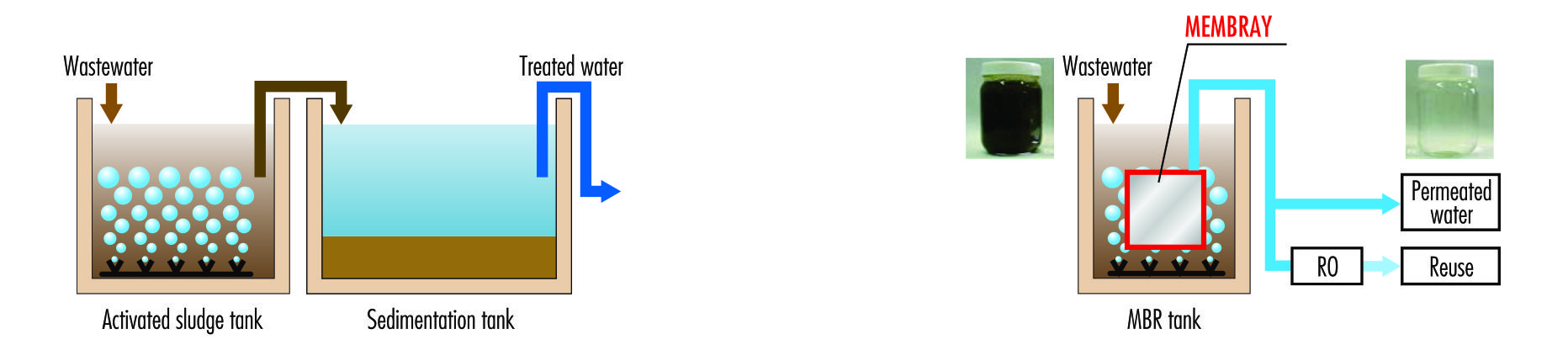

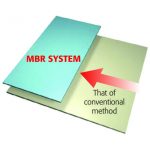

Membrane Bio Rector (MBR) process is a combination of biological wastewater treatment and membrane filtration. Biodegradable pollution is reduced using bacteria and microorganisms. Following biological treatment, the activated-sludge is separated from the threated water by a microfiltration membrane. MBR is the latest technology to treat municipal wastewater as well as various industrial wastewater from around the world. TORAY’s “MEMBRAY” module for MBR systems, developed over 25+ years of experience in the membrane industry, removes suspended solids (SS) and microorganisms such as Escherichia coli and Cryptosporidium from the sludge liquid much more effectively than the conventional sedimentation process, which achieves extraordinarily high effluent quality. The MBR is used to treat domestic wastewater reuse in hotel and commercial building, also in industrial wastewater since MBR has excellence in spare requirement. GLS provides two types of MBR, TMR 140 for large-sized sewage treatment plant and TMR 090 for small-sized sewage treatment plant.

TMR 140

TMR140 series are large-sized module which is suitable for large-sized sewage treatment plant.

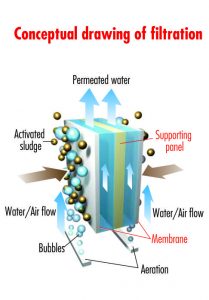

Toray’s Membrane Bioreactor (MBR) process is a combination of biological wastewater treatment and membrane filtration.

Biodegradable pollution is reduced using bacteria and microorganisms. Following biological treatment, the activated-sludge is separated from the treated water by a microfiltration membrane.

MBR Technology Explain

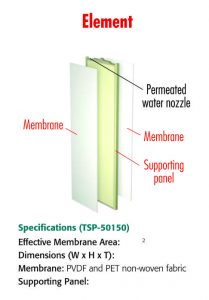

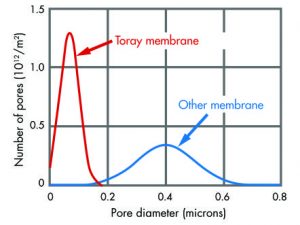

Toray’s MEMBRAY MBR Membranes are PVDF flat sheet membranes with a PET non-woven support layer. The nominal pore size is 0/08 microns with a narrow pore size distribution. Toray membrane elements with a 1.4 m2 or a 0.9 m2 membrane area are joined to our membrane module. These modules are composed of 50 to 200 membrane elements.

Toray’s advance membrane separation technology and nanotechnology create better MBR modules.

The “MEMBRAY” submerged flat sheet membrane module, when used as a component of a membrane bioreactor (MBR) system, effectively removes suspended solids. This innovative microfiltration module in a plate-and-frame configuration with flat sheet membranes was developed thanks to over 25 years of experience in high-quality membrane products and our non-compromise R&D, manufacturing and application expertise.

MBR with “MEMBRAY” Submerged Flat Sheet Membrane Module

MBR technology enhances wastewater treatment efficiency

- Using membranes to separate sludge ensure much higher quality for trated water free from suspended solids. Combination with RO membranes allows producing water quality as good as polable water.

- Membranes can retain activated sludge at high concentrations, allowing BOD as well as nitrogen to be removed more efficiently.

- Unique membrane configuration having an immense number of minuscule pores delivers stable high water permeability with minimal clogging and highe permeated water quality.

Smaller footprints

- The module can be submerged directly in an activated sludge tank for combining biological treatment and membrane separation. It eliminates the sedimentation or sludge concentration process.

- More effective biological treatment allows activated sludge tank size to be reduced.

Fewer chemical cleaning requirements and coarse screen pretreatment

- The palte-and-frame configuration that employs flat sheet membranes is inherently stronger against fouling than the hollow fiber membrane configuration. Therefore, it results in fewer chemical cleaning requirements.

- Reduced module fouling from human hair and other obstructive subtances allow coarse screening as a pretreatment process.

Energy efficient

- “MEMBRAY” consumes less energy compared to hollow fiber membrane due to more effective scouring aeration and lower trans-membrane pressure.

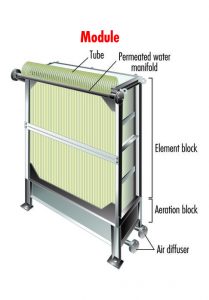

The “MEMBRAY” module configuration comprises an element block and an aeration block. The element block contains a number of membrane elemetns stacked at equal intervals, each of which has flat sheet membranes attached on both sides of a supporting panel. Each element is connected via tube to a permeated water menifold. The aeration block consists of air diffusers used to supply air.

Why “MEMBRAY” performace ranks with the best

Guaranteed high water permiability and high effluent quality

- Many 0.08 micron pores on the membrane surface effectively eliminate 0.1 micron+ particles to improve effluent quality.

- Uniform pore size results in consistently high permeability with minimal pore clogging

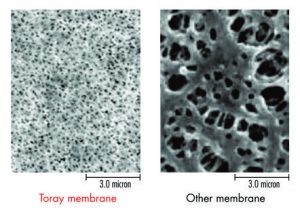

Unique membrane structure

Numerous small-diameter pores are distributed evently throughout the membrane surface with a narrow diameter distribution. This structure ensures higher treated water quality and minimizes membrane fouling and pore clogging for consistently high water permeability.

Better membrane materials

Using PVDF (Polyvinylidene Flouride) for the functional layer of the membrane and PET(Polyester) non-woven fabric as the base layer allows the membrane to exhibit supperior physical strength and chemical stability.

Flat sheet type membrane with modified surface nature

The membrane has a simple flat sheet configuration. This configuration and the modified membrane surface nature allow very effective cleaning by a stream of water generated upward as scouring air is diffused below it. This mechanism provides extremely stable filtration as the membrane does not allow sludge to adhere to its surface.

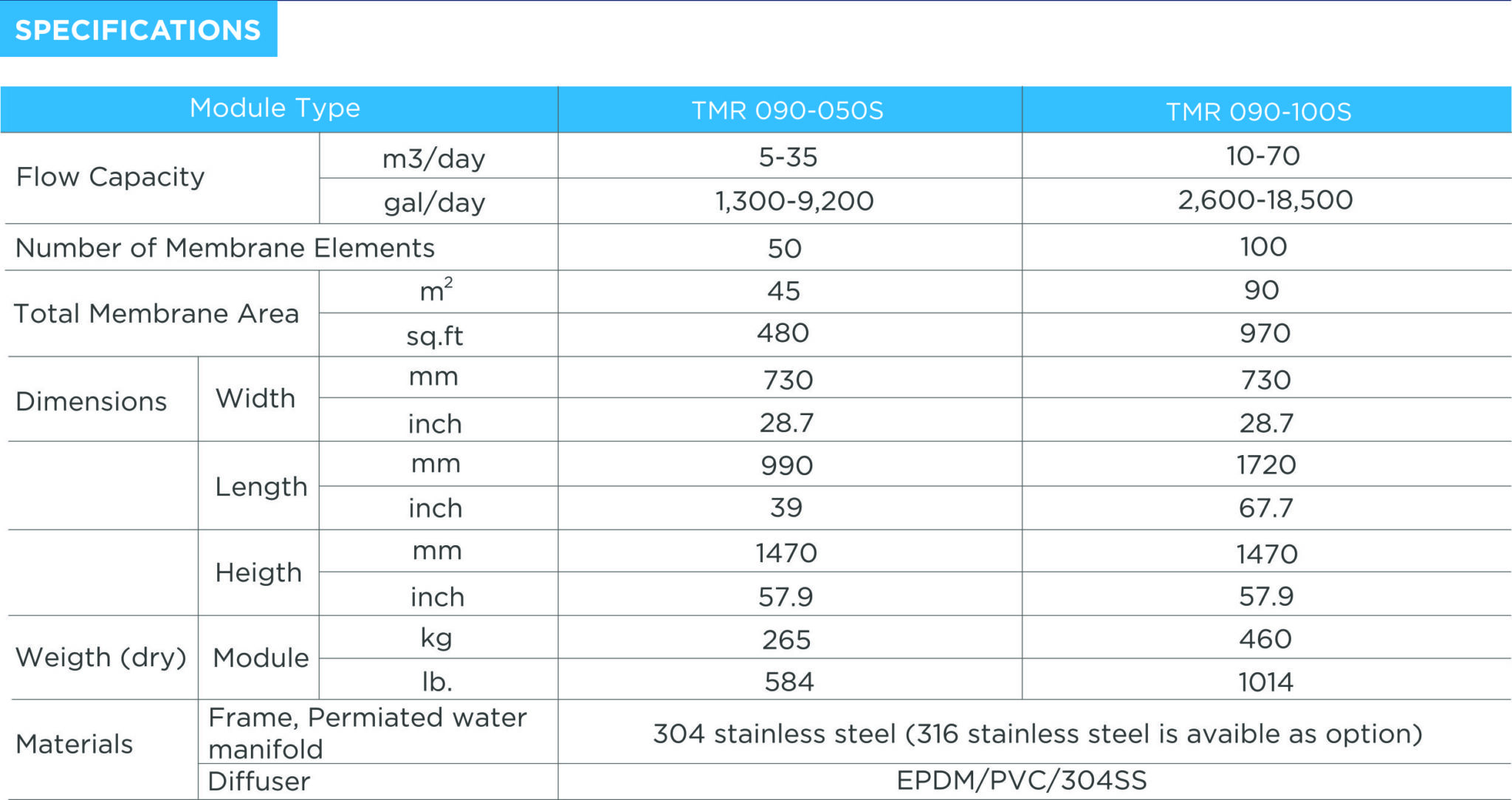

TMR 090

TMR090 series are small-sized module which is suitable for contanerized package plant.