Introduction — Why Thermal vs Membrane Desalination Matters

Global industries — from hospitality to power generation — rely on desalination systems to secure sustainable water resources. Among the most widely used technologies are thermal vs membrane desalination, two core processes that define how saltwater is transformed into freshwater for industrial use. As demand grows, choosing the right desalination system becomes crucial for efficiency, cost, and sustainability.

In simple terms, desalinasi adalah proses menghilangkan kadar garam dari air laut atau air payau agar menjadi air bersih yang dapat digunakan untuk berbagai kebutuhan industri.

👉 Learn the fundamentals of desalination from ScienceDirect Topics.

Understanding Thermal Desalination Systems

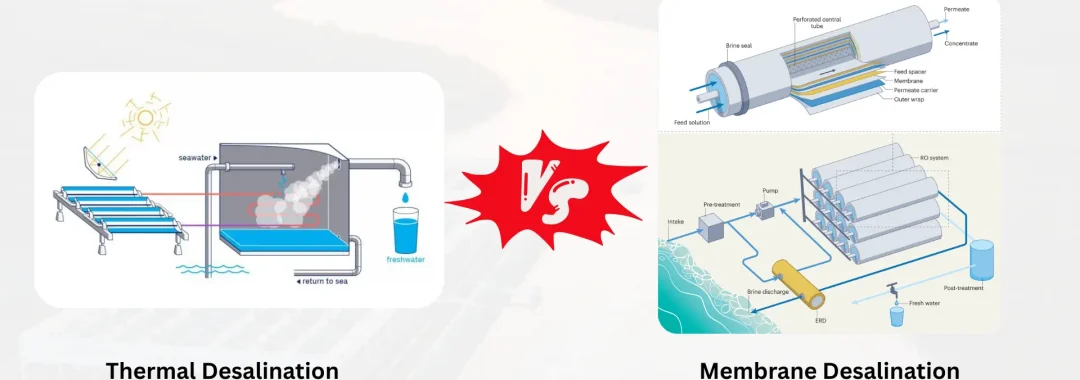

Thermal desalination, one of the two main approaches in thermal vs membrane desalination, uses heat to evaporate seawater, then condenses the vapor into fresh water — leaving salt and minerals behind. It’s a time-tested process, often applied in large-scale plants that can also recover waste heat from power generation.

Main Types of Thermal Desalination

- Multi-Stage Flash (MSF)

- Multi-Effect Distillation (MED)

- Vapor Compression (VC)

Thermal systems are reliable and handle high-salinity feed water, making them ideal for coastal power plants and heavy industries. However, they are energy-intensive and require significant capital investment.

📖 Learn more about phase-change desalination technologies in this MDPI review on thermal desalination.

Internal link: For a broader explanation of proses desalinasi air laut, visit Proses Desalinasi Air Laut.

Understanding Membrane Desalination Systems

Membrane desalination is a pressure-driven process that pushes water through a semi-permeable membrane, separating dissolved salts and impurities. The most common form, Reverse Osmosis (RO), dominates today’s desalination market due to its scalability and energy efficiency.

Types of Membrane Desalination

- Reverse Osmosis (RO)

- Electrodialysis (ED)

- Forward Osmosis (FO)

- Capacitive Deionization (CDI)

Membrane systems are compact, energy-efficient, and modular — perfect for food & beverage, hospitality, and manufacturing industries. They require effective pre-treatment and anti-scaling control to prevent fouling.

💧 Learn more in this MDPI study on membrane-based desalination systems.

Internal links:

- For membrane technology, visit Reverse Osmosis Membrane.

- For chemical treatment solutions, check Anti Scaling Agent untuk RO.

- For alternative filtration, explore Hollow Fiber Membrane.

Key Differences in Thermal vs Membrane Desalination

| Criteria | Thermal Desalination | Membrane Desalination |

|---|---|---|

| Core Process | Evaporation & condensation | Filtration through membranes |

| Energy Source | Heat / Steam | Electricity / Pressure |

| Cost per m³ | Higher | Moderate to Low |

| Water Type | High-salinity seawater | Brackish & lower salinity |

| Maintenance | Moderate | Higher (membrane fouling) |

| Ideal Industries | Power, Oil & Gas | Hospitality, F&B, Manufacturing |

📘 For advanced comparisons, read Elsevier’s study on hybrid desalination systems.

Internal link opportunity:

See Sistem Desalinasi RO for RO-based system examples used in membrane desalination.

Hybrid Desalination Systems: Combining Thermal and Membrane Technologies

Hybrid desalination integrates membrane (RO) and thermal (MED/MSF) technologies to improve efficiency and reduce waste. These systems:

- Optimize energy consumption using waste heat

- Improve water recovery rates

- Minimize brine disposal volumes

🔗 Explore how industries reuse waste heat for thermal desalination on SciELO.

Internal link idea: Showcase a real-world case by linking to GLS Completes Desalination Project.

Environmental & Economic Impact of Desalination Types

Thermal systems consume more energy but can utilize residual heat from industrial operations, reducing total emissions. Membrane systems, while energy-efficient, must manage chemical usage and brine disposal.

🧪 For an in-depth environmental comparison, explore the MDPI report on advances in desalination methods.

🌍 For sustainable development insights, visit the UNESCO Water Portal.

Which Desalination Type Is Right for Your Industry?

| Industry | Recommended System | Reason |

|---|---|---|

| Power & Energy | Thermal / Hybrid | Uses waste heat efficiently |

| Hospitality & Resorts | Membrane | Compact, low-energy systems |

| Food & Beverage | Membrane | High purity, consistent output |

| Oil & Gas | Thermal | Handles high-salinity feed |

| Municipal Supply | Hybrid | Balances efficiency and cost |

💡 The right thermal vs membrane desalination choice depends on salinity, energy source, and budget. For a tailored solution, contact PT Gapura Liqua Solutions, Indonesia’s trusted partner for complete water treatment and desalination systems.

Conclusion — Choosing Between Thermal and Membrane Desalination

Both thermal and membrane desalination play essential roles in modern water management.

- Choose thermal for high-salinity, large-scale, or power-linked operations.

- Choose membrane for energy-efficient, modular, and scalable applications.

By understanding thermal vs membrane desalination, industries can make smarter, sustainable decisions.

With years of expertise in water treatment engineering, Gapura Liqua Solutions delivers end-to-end solutions for both technologies — helping businesses achieve reliable, efficient, and environmentally responsible water supply systems.