How a DAF System Works: An Engineer’s Guide to Wastewater Clarification

For a CEO, Head of a Water Treatment Plant, or a Procurement leader, making significant capital investments in equipment requires a clear understanding of the technology’s function and its impact on the bottom line. When it comes to industrial wastewater, one of the most critical challenges is the effective removal of suspended solids and oils. Consequently, understanding how a DAF system works is essential, as this technology represents a cornerstone of modern, efficient, and compliant wastewater treatment. This guide will demystify the Dissolved Air Flotation (DAF) process, translating complex engineering into a clear business case.

What is a DAF System in Wastewater Treatment?

First and foremost, a Dissolved Air Flotation (DAF) system is a highly efficient water clarification technology. Its primary purpose is to separate suspended solids (TSS), fats, oils, and grease (FOG), and other low-density particles from a liquid stream.

In essence, a DAF is the core of many Wastewater Treatment Plant (WWTP) pre-treatment stages. It tackles problematic contaminants like high TSS levels and Fats, Oils, and Grease (FOG) head-on. By removing these pollutants early, a DAF system significantly reduces the load on downstream biological treatment processes, lowers overall chemical consumption, and is often the key to achieving regulatory compliance for the final effluent.

The Core Principle: How DAF Works Using Micro-Bubble Flotation

The genius of a DAF system lies in its use of buoyancy. Unlike a conventional clarifier that waits for heavy particles to settle to the bottom, a DAF system does the opposite: it uses millions of microscopic air bubbles to float lighter, suspended particles to the surface.

This process is exceptionally effective for contaminants that are difficult to settle, particularly the oils and greases common in industrial wastewater from food processing, oil and gas, and manufacturing facilities.

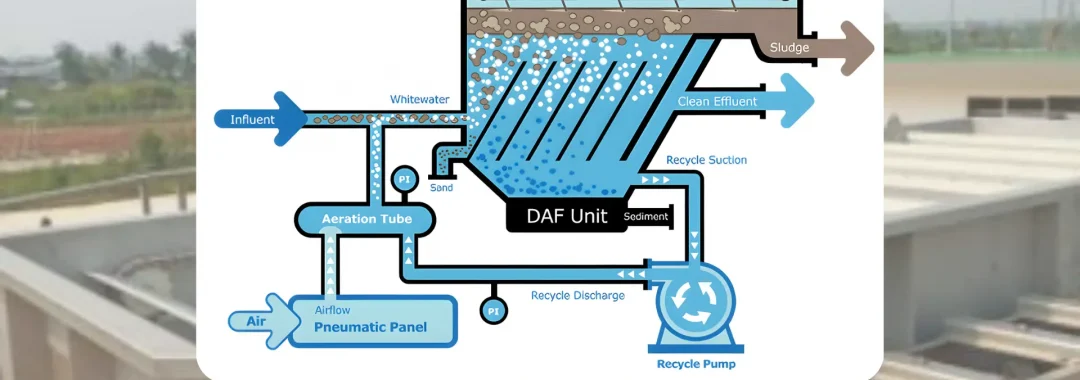

A Step-by-Step Breakdown of the DAF Process

Understanding how a DAF system works is best done by breaking it down into four distinct, sequential steps.

Step 1: Chemical Pre-Treatment (Coagulation & Flocculation)

Raw wastewater first enters a pre-treatment stage where chemicals are added to prepare the contaminants for removal. This is a critical step for improving overall Water Quality.

- Coagulation: A coagulant is dosed into the water to neutralize the electrical charge of the tiny suspended particles, allowing them to start clumping together.

- Flocculation: Next, a long-chain polymer (a flocculant) is added. This chemical acts like a net, gathering the small clumps into larger, more robust flocs that are easier for the air bubbles to capture and lift.

Step 2: Air Saturation in the Saturator

In parallel, a portion of the clean, treated water from the DAF outlet (known as white water) is recycled. This recycled stream is pumped into a specialized pressure vessel called a saturator. Inside the saturator, the water is mixed with compressed air under high pressure (typically 4-6 bar). This pressure forces a large amount of air to dissolve directly into the water, creating a supersaturated solution.

Step 3: Injection and Micro-Bubble Formation

This supersaturated, air-rich “white water” is then injected into the DAF flotation tank, where it mixes with the flocculated wastewater from Step 1. As the pressurized water enters the tank, the pressure is suddenly released to atmospheric levels. This pressure drop immediately causes the dissolved air to precipitate out of the solution, forming a cloud of extremely fine micro-bubbles. These bubbles are typically 30-50 microns in diameter, which is the optimal size for attaching to the suspended flocs.

Step 4: Flotation and Sludge Skimming

The cloud of micro-bubbles adheres to the surface of the flocs created in Step 1. As a result, the combined buoyancy of the bubbles and the floc lifts the solids to the surface of the tank. This process forms a stable layer of concentrated sludge on top. A mechanical skimmer then slowly moves across the surface, scraping the floated sludge into a collection hopper. The now-clarified water exits from the bottom of the DAF tank for further treatment or discharge.

Why This Matters for You: From Technology to Business Strategy

As a decision-maker, understanding the “how” is important, but the “why” is critical. The efficiency of a DAF system translates directly into business benefits.

Reduced Operational Costs

An efficient DAF system can remove 90-99% of TSS and FOG. This high removal rate means less load on downstream processes, reducing the energy and chemical costs of secondary treatment. Furthermore, the sludge produced is thicker (3-5% solids) than conventional methods, significantly reducing the volume and cost of sludge disposal.

Ensured Regulatory Compliance

The high efficiency of DAF ensures that your plant’s effluent can consistently meet the stringent Wastewater Quality Standards set by Indonesian authorities, such as the Minister of Environment and Forestry Regulation. This is a crucial factor in risk mitigation and avoiding costly penalties.

Finding a Reliable EPC Partner

Ultimately, the performance of a DAF system depends heavily on its design, engineering, and integration into your overall WWTP. This is why partnering with an experienced EPC (Engineering, Procurement, Construction) company is paramount. A reliable partner ensures the system is sized and configured correctly for your specific wastewater characteristics.

Conclusion: Partner with PT. GLS for Expertly Engineered DAF Solutions

Understanding how a DAF system works reveals its strategic value in any modern industrial Wastewater Treatment Plant (WWTP). It is a robust, efficient technology that directly contributes to lower costs, reliable uptime, and guaranteed compliance.

At PT. Gapura Liqua Solutions (PT. GLS), we are more than just an equipment supplier; we are your end-to-end strategic partner. Our expertise as an EPC and BOO (Build, Own, Operate) solutions provider ensures that your DAF system is not just a piece of hardware, but a fully integrated, high-performing asset. We handle the complexity of water treatment, from design to long-term OMS (Operation, Maintenance, Service), allowing you to focus on your core business.

To discuss how a DAF system can be integrated into your facility, speak with our experts.

Frequently Asked Questions (FAQ)

1. What is the DAF process? The DAF (Dissolved Air Flotation) process is a water clarification method that separates suspended solids, oils, and grease from water by attaching microscopic air bubbles to them, causing them to float to the surface for removal.

2. What is DAF? DAF stands for Dissolved Air Flotation. It is a highly efficient and compact piece of equipment used in industrial and municipal wastewater treatment.

3. How does DAF work in a WWTP? In a Wastewater Treatment Plant (WWTP), a DAF unit typically serves as a primary treatment step. It removes the bulk of suspended solids and FOG after chemical pre-treatment, which protects and reduces the load on subsequent biological treatment stages, making the entire plant more efficient.

4. What is DAF in engineering? In engineering terms, DAF is a separation technology that leverages Henry’s Law, which states that the amount of dissolved gas in a liquid is proportional to its partial pressure above the liquid. The system creates a supersaturated solution of air in water under pressure, and then releases that pressure to generate a cloud of micro-bubbles for flotation.