Enhancing Industrial Water Pre-treatment with Self Sterilizing Media Filter Technology

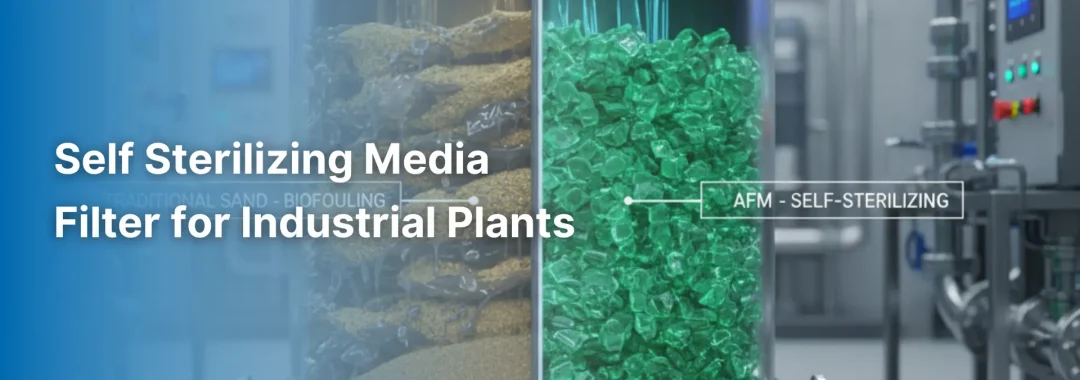

In the demanding environment of Indonesian industrial utilities, the efficiency of pre-treatment systems dictates the lifespan of the entire water circuit. As facilities strive for higher operational uptime, many are pivoting toward the self sterilizing media filter, specifically utilizing Activated Filter Media (AFM). This shift is driven by the need to combat the persistent threat of biological growth within filtration beds, which often compromises downstream reverse osmosis membranes.

The Biofouling Challenge in Industrial Filtration

Traditional filtration methods often become breeding grounds for bacteria. When organic matter is trapped in standard media, it creates a biofilm that leads to “channeling.” This reduces the quality of the water and increases the frequency of backwashing.

Why Conventional Sand Filters Fail in Industrial Utilities

Sand is silica-based and chemically inert, allowing bacteria to colonize the surface of the grains. This biofilm acts as a “glue,” sticking grains together and increasing the pressure drop across the vessel. For a Facility Manager, this means higher energy costs and inconsistent water quality.

The AFM Advantage: A True Self Sterilizing Media Filter

Activated Filter Media (AFM) is a direct replacement for sand, manufactured from green glass and activated through a unique chemical and thermal process. This results in a self sterilizing media filter that prevents bacteria from ever attaching to the surface.

| Performance Metric | Standard Silica Sand | AFM (Self-Sterilizing) |

| Filtration Grade | 20 microns | < 5 microns |

| Bio-Resistance | None (Biofilm forms) | High (Self-sterilizing) |

| Backwash Water | High volume required | 50% less water used |

| Lifespan | 2–3 years | Over 15 years |

Catalytic Oxidation and Bio-Resistance Explained

The surface of AFM has a high negative charge and catalytic properties. When water flows through, it creates small amounts of free radicals (OH) on the surface, which act as a disinfectant. This is what makes it a self sterilizing media filter. By removing the biological load at the pre-treatment stage, you significantly improve BWRO membrane performance and reduce the need for aggressive chemical cleaning.

Why PT. Gapura Liqua Solutions Integrates AFM in Systems

At PT. Gapura Liqua Solutions (GLS), we specialize in end-to-end engineering that prioritizes long-term reliability. We integrate self sterilizing media filter technology into our SWRO and BWRO systems because it allows our clients to focus on their core business without worrying about sudden utility failures.

By utilizing the keunggulan sistem air RO equipped with AFM, industrial plants in Indonesia can achieve lower TDS levels and superior permeate quality while reducing their environmental footprint.

Conclusion: Sustainable Water Reliability for Indonesian Industry

Investing in a self sterilizing media filter is a strategic decision for any technical director aiming for resource recovery and efficiency. AFM technology provides the stability required for modern industrial processes, ensuring that your water supply remains a silent partner in your success, not a constant maintenance headache.

To upgrade your current filtration system or design a new utility plant, Contact us at GLS.

FAQ Section

Q: How does a self sterilizing media filter reduce chemical costs?

A: Since the media prevents biofilm formation, there is less organic matter reaching the RO membranes. This reduces the frequency of CIP (Cleaning In Place) and the volume of biocides required.

Q: Can I replace my existing sand with AFM?

A: Yes, AFM is a 1:1 replacement for sand in existing pressure vessels, though we recommend a system audit to optimize backwash flow rates.

Q: Is this technology effective for seawater desalination?

A: Absolutely. In seawater applications, biofouling is the leading cause of membrane failure. AFM provides a critical protective barrier.