Optimasi Efisiensi Teknologi Reverse Osmosis untuk Keberlanjutan Industri

Dalam lanskap industri Indonesia yang kompetitif, gangguan pada utilitas air berarti kerugian finansial. Kegagalan sistem pengolahan sering kali berujung pada penghentian produksi secara mendadak. Memahami efisiensi teknologi reverse osmosis bukan sekadar pilihan teknis. Ini adalah strategi manajemen risiko bagi para direktur teknis dan manajer fasilitas.

Tantangan Operasional: Mengapa Sistem RO Standar Sering Gagal?

Banyak perusahaan manufaktur menghadapi masalah kronis pada sistem pemurnian air mereka. Masalah utama biasanya berkisar pada tingginya biaya operasional (OPEX) dan rendahnya masa pakai komponen.

Beberapa faktor kegagalan meliputi:

- Biofouling: Akumulasi mikroorganisme yang menyumbat pori membran secara prematur.

- High Pressure Drop: Penurunan tekanan yang drastis akibat desain sistem yang tidak presisi.

- Permeate Quality: Fluktuasi kualitas air hasil yang tidak memenuhi standar proses industri.

Tanpa penanganan tepat, beban biaya penggantian reverse osmosis membrane akan membengkak secara signifikan.

Solusi Teknis: Integrasi Engineering dan Presisi Material

Mencapai efisiensi teknologi reverse osmosis memerlukan pendekatan holistik. PT. Gapura Liqua Solutions (GLS) menerapkan standar engineering yang melampaui sekadar perakitan komponen.

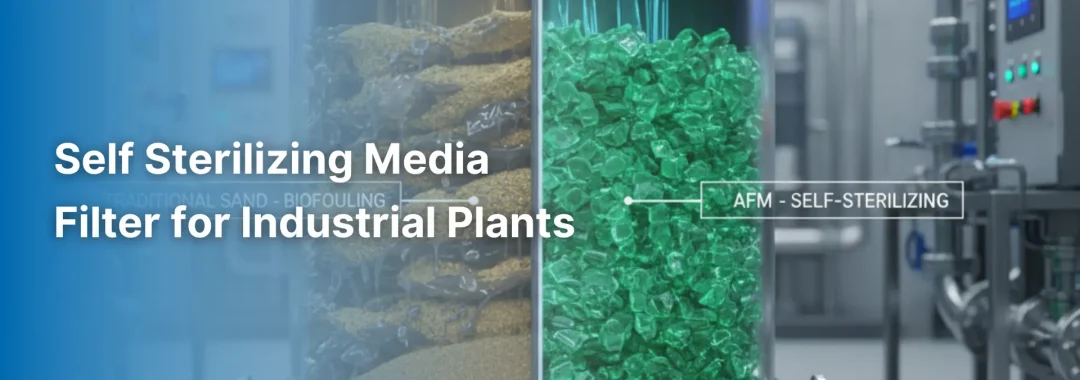

1. Pre-treatment Tingkat Lanjut

Kami menggunakan media filtrasi aktif seperti Activated Filter Media (AFM). Teknologi ini memiliki sifat katalitik yang mencegah penggumpalan bakteri. Hal ini secara langsung menurunkan risiko membrane fouling.

2. Monitoring TDS dan Laju Aliran

Sistem kami dirancang untuk menangani variasi TDS levels yang ekstrem, baik untuk aplikasi Sea Water (SWRO) maupun Brackish Water (BWRO). Dengan pemantauan real-time, risiko kerusakan mekanis akibat kerak dapat dimitigasi sejak dini. Anda dapat mempelajari lebih lanjut mengenai BWRO membrane performance untuk data teknis lebih dalam.

Perbandingan: Standar Industri vs. Solusi GLS

| Fitur Teknis | Praktek Industri Standar | GLS Engineered Solutions |

| Desain Sistem | Rakitan komponen generik | Custom-engineered sesuai feed water |

| Manajemen Membran | Penggantian reaktif | Prediktif berbasis data performa |

| Konsumsi Energi | Tinggi (tanpa optimasi tekanan) | Rendah (dengan Energy Recovery Devices) |

| Dukungan Teknis | Terbatas pada penjualan | Kontrak O&M menyeluruh |

Memilih Mitra Strategis: Keunggulan GLS

PT. Gapura Liqua Solutions memahami bahwa air adalah nadi industri Anda. Kami menawarkan keunggulan sistem air RO yang terintegrasi dengan layanan EPC (Engineering, Procurement, and Construction).

Fokus kami adalah Resource Recovery. Kami membantu industri tidak hanya memurnikan air, tetapi juga mengoptimalkan setiap tetes yang digunakan melalui sistem yang andal dan efisien. Fokuslah pada bisnis inti Anda, sementara kami menangani kompleksitas pengolahan air.

Untuk pengadaan komponen cepat, Anda juga dapat mengunjungi Official Store kami di Tokopedia.

Kesimpulan: Investasi untuk Masa Depan

Meningkatkan efisiensi teknologi reverse osmosis adalah investasi jangka panjang. Dengan sistem yang tepat, perusahaan Anda dapat menekan biaya maintenance dan meningkatkan keberlanjutan operasional. Pastikan sistem Anda didukung oleh keahlian teknis kelas dunia untuk hasil yang konsisten.

Konsultasikan kebutuhan sistem air industri Anda dengan tim ahli kami melalui halaman Contact Us.

FAQ: Pertanyaan Teknis Pengambil Keputusan

1. Bagaimana cara menghitung ROI dari upgrade sistem RO? ROI dihitung berdasarkan penurunan frekuensi pembersihan membran (CIP), penghematan energi melalui variable speed drives, dan pengurangan biaya penggantian membran tahunan.

2. Apakah GLS dapat melakukan audit pada sistem RO yang sudah ada? Ya, kami menyediakan layanan audit teknis untuk mengidentifikasi bottleneck operasional dan memberikan rekomendasi peningkatan efisiensi secara spesifik.

3. Apa standar kualitas permeate yang dijamin oleh teknologi GLS? Sistem kami dirancang untuk memenuhi standar ketat sesuai kebutuhan spesifik industri, mulai dari standar air umpan boiler hingga proses farmasi yang mengacu pada regulasi internasional seperti World Health Organization (WHO) atau standar lokal Kementerian Perindustrian.