Industrial Salt Water Treatment: Securing Operations Against Scarcity

For facility managers and procurement heads across Indonesia, securing a reliable, high-quality water supply is becoming increasingly complex. As freshwater sources become scarcer or contaminated due to seawater intrusion, industries are forced to look towards alternative sources: seawater and brackish groundwater. Consequently, implementing effective industrial salt water treatment is no longer an option; it is a strategic necessity for business continuity.

PT. Gapura Liqua Solutions (GLS) understands that your core business is not managing water treatment plants. However, without a reliable supply of process water, core operations grind to a halt. This article outlines the critical importance of professional desalination strategies.

The High Cost of Ignoring Salinity in Industrial Water

Utilizing water with high Total Dissolved Solids (TDS) without adequate treatment is a recipe for disaster. While the immediate availability of brackish or seawater might seem like a solution, the hidden costs are substantial.

Impact on Assets and Operational Continuity

Untreated saline water wreaks havoc on industrial infrastructure. Specifically, chlorides present in salt water are highly corrosive to metals, leading to rapid deterioration of piping, boilers, and cooling towers. Furthermore, high mineral content causes scaling, which reduces heat transfer efficiency and increases energy consumption.

Ultimately, these issues lead to unplanned downtime and expensive equipment replacement. Therefore, investing in a robust industrial salt water treatment system is essentially an insurance policy for your entire production facility.

Industrial Salt Water Treatment as a Strategic Solution

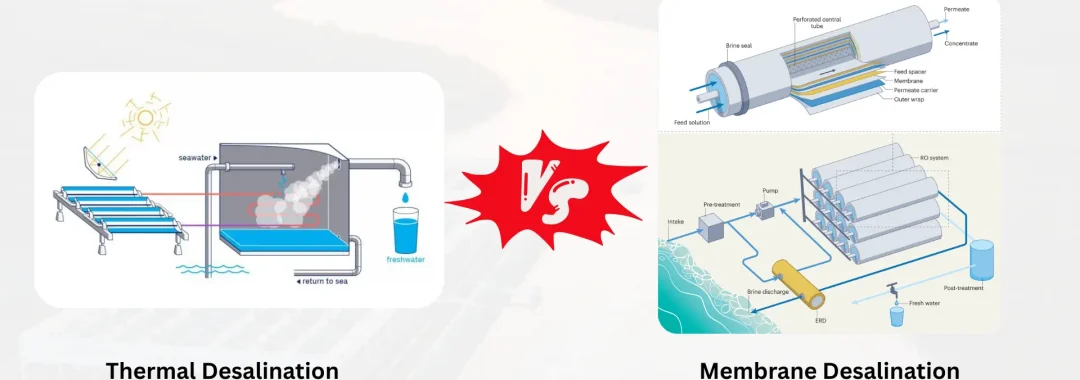

Modern desalination technology allows industries to convert virtually any saline source into high-purity process water. The most prevalent and energy-efficient method today is Reverse Osmosis (RO).

Depending on the source water salinity, systems are categorized as Seawater Reverse Osmosis (SWRO) or Brackish Water Reverse Osmosis (BWRO). To understand the benefits better, you can read about the general advantages of RO water systems.

The Role of Advanced Membrane Technology

At the heart of any RO system are the membranes. These semi-permeable barriers separate salts from water molecules under high pressure. The selection of the right Reverse Osmosis Membrane is critical and depends heavily on the specific feed water chemistry.

For facilities dealing with brackish groundwater, understanding factors affecting BWRO membrane performance is essential for optimizing lifespan and energy usage. Utilizing the correct technology turns a problematic water source into a secure, long-term asset.

Why Engineering Expertise Defines Long-Term Success

Buying equipment is easy; ensuring it runs efficiently for twenty years is difficult. Many industrial desalination projects fail not because of the technology, but due to poor system design or inadequate maintenance.

An effective industrial salt water treatment plant requires precise engineering, proper pre-treatment protocols, and energy recovery devices to keep operational expenditures (OPEX) manageable. According to the International Desalination Association, energy consumption remains a key factor in plant viability, emphasizing the need for efficient design.

Beyond Installation: The Importance of O&M

Successful water management requires a long-term view. GLS provides end-to-end systems, meaning we don’t just supply hardware; we ensure operational continuity. This includes long-term Operations & Maintenance (O&M) support, ensuring compliance with environmental regulations, and managing consumables.

Real-world application of this expertise is crucial. You can see examples of our ongoing commitment to operational excellence in our recent project updates on LinkedIn.

Conclusion

Facing water scarcity requires proactive measures. By adopting advanced industrial salt water treatment, Indonesian industries can secure their water future against operational risks. However, the technology is only as good as the partner behind it.

GLS offers the expertise to deliver reliable, end-to-end desalination solutions, allowing you to focus entirely on your core business. For convenience, you can even find essential components through our official Tokopedia store.

Do not compromise on water security. Contact PT. Gapura Liqua Solutions today to discuss your specific water challenges.

FAQ Section

Q: What is the difference between SWRO and BWRO in industrial treatment?

A: SWRO (Seawater Reverse Osmosis) treats water with very high salinity (typically >30,000 ppm TDS), requiring higher pressures and energy. BWRO (Brackish Water Reverse Osmosis) treats water that is saltier than fresh water but less salty than seawater (typically 1,000–10,000 ppm TDS), often found in coastal groundwater.

Q: How does GLS ensure the long-term reliability of a salt water treatment plant?

A: We go beyond just supplying equipment. We provide comprehensive engineering, proper pre-treatment design to protect membranes, and offer long-term Operations & Maintenance (O&M) contracts to ensure continuous, optimal performance.

Q: Is industrial salt water treatment cost-effective for my facility?

A: While the initial investment can be significant, the cost of not having reliable water—through downtime, corroded assets, or buying expensive trucked water—is often much higher. Modern energy recovery devices have also significantly reduced the OPEX of desalination.

Q: Can GLS handle high-volume water requirements for large industries?

A: Yes. GLS specializes in end-to-end industrial-scale solutions, designing systems tailored to the specific volume and quality requirements of large manufacturing and processing facilities.