In the quest for efficient water treatment solutions in Indonesia, businesses are turning to innovative technologies to meet the growing demand for clean water. One such revolutionary technology making waves is the Hollow Fiber Membrane. Surely In this article, PT Gapura Liqua Solutions will delve into the intricacies of this advanced water treatment solution, specifically tailored for the Indonesian market.

Understanding Hollow Fiber Membranes

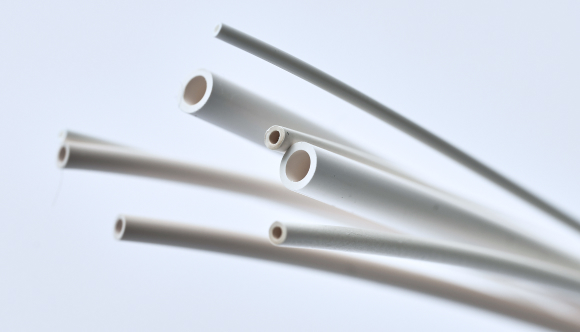

What is a Hollow Fiber? Hollow fibers are microscopic, tube-like structures with a hollow center, designed for optimal filtration efficiency. Although these fibers are typically made from materials such as polyethylene or polysulfone, the durability and longevity in water treatment applications is surely guaranteed.

Materials Used in Hollow Fiber Membranes The choice of materials in hollow fiber membranes is crucial for their performance and lifespan. Additionally polyethylene and polysulfone are popular choices due to their resistance to chemical degradation and fouling, ensuring consistent filtration results over time.

Advantages

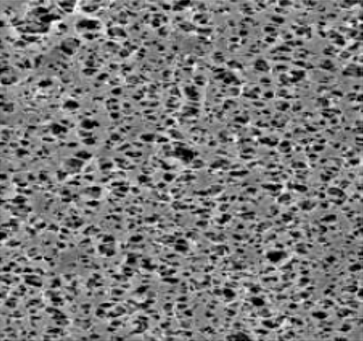

High Filtration Efficiency Hollow fiber membranes boast high filtration efficiency, removing impurities, bacteria, and even viruses from water. This efficiency is vital for businesses seeking reliable water treatment solutions.

Compact Design and Space Efficiency The compact design of this systems allows businesses to optimize space without compromising on filtration capacity. This is particularly advantageous for industries facing space constraints comparatively.

Versatility in Applications From municipal water treatment to industrial purification and even sea water treatment, hollow fiber membranes exhibit versatility in various applications. Therefore this adaptability makes them a go-to solution for a wide range of water treatment needs.

Applications of Hollow Fiber Filters

Municipalities can benefit from the efficiency and compact design of hollow fiber membrane systems. Industries can customize the systems to address specific contaminants and achieve high-quality water for their processes.

The ability of hollow fiber membranes to effectively filter sea water opens new possibilities for industries requiring desalination processes. This can be a game-changer for businesses operating in coastal areas.

Implementing Hollow Fiber Membrane Technology

Selecting the appropriate filtration system is the first crucial step in implementing hollow fiber membrane technology. Actors such as water quality, flow rates, and specific contaminants should be considered for optimal system performance at first.

The ultrafiltration process is a key component for this technology, removing particles and microorganisms, a reliable barrier against contaminants.

Explore real-world examples of successful implementations, not only showcasing the positive impact on water quality but also operational efficiency.

Price Factors

The initial investment may seem significant, but focus on the long-term benefits, low maintenance costs and lifespan. The ROI considering factors are energy savings, reduced chemical usage, and improved overall water treatment efficiency.

Conclusion

As Indonesia faces challenge of access to clean water, hollow fiber membrane technology emerges as a powerful solution for businesses. By understanding the advantages, applications, and implementation processes, Indonesian entrepreneurs can make informed decisions to revolutionize their water treatment strategies. Above all embrace the future of water treatment with hollow fiber membranes and contribute to a sustainable and water-secure Indonesia.

Follow us on Social Media