Efficient Media Filter: The Core of Sustainable Water Treatment in Indonesia

In the dynamic landscape of Indonesia’s industrial growth, access to and management of clean water are paramount. Industries across the archipelago, from bustling manufacturing plants to extensive agricultural operations, face increasing pressure to optimize water usage, meet stringent discharge regulations, and ensure consistent process water quality. At the heart of these critical objectives lies a technology that is both fundamental and transformative: the efficient media filter.

An efficient media filter is not merely a component; it is, in fact, a strategic investment. It acts as the cornerstone of any robust water treatment system. Such a filter ensures water entering production processes remains free from harmful particles. This in turn protects machinery, enhances product quality, and significantly reduces operational overheads. For businesses in Indonesia navigating water scarcity, environmental compliance, and cost efficiency, implementing the right filtration technology is no longer optional; it’s a necessity.

This comprehensive guide will delve into what makes an efficient media filter so vital. Specifically, it will focus on advanced solutions like the GLS Series—GLS2000, GLS3000, and GLS4000. We will, moreover, explore their operational principles, diverse applications, and the tangible benefits they offer to industries across Indonesia, from desalination plants to the oil and gas sector.

Why an Efficient Water Filtration System is Important for Industries in Indonesia

Indonesia’s diverse industrial landscape, coupled with its unique geographical and climatic conditions, presents distinct challenges for water management. Industries frequently draw water from various sources—rivers, boreholes, or even municipal supplies. Each of these sources typically carries its own set of impurities, ranging from suspended solids and organic matter to potential biological contaminants. Without effective filtration, these impurities can lead to a cascade of problems.

Challenges of Water Management in the Industrial Sector

The challenges in industrial water management in Indonesia are indeed multifaceted:

- Operational Downtime: Unfiltered water can cause fouling, scaling, and corrosion in machinery. This often leads to frequent breakdowns and costly production halts.

- Product Quality Compromise: Impurities can directly affect the quality, purity, and consistency of manufactured goods. This, consequently, impacts brand reputation and market competitiveness.

- Increased Maintenance Costs: Regular cleaning and replacement of damaged equipment due to poor water quality significantly inflate operational budgets.

- Environmental Compliance: Strict regulations concerning wastewater discharge necessitate effective pre-treatment. This helps avoid fines and environmental damage.

- Water Scarcity and Sustainability: Growing demand for water resources pushes industries towards more efficient water reuse and recycling. This process, naturally, relies heavily on advanced filtration.

Key Benefits of Efficient Media Filters

An efficient media filter directly addresses these challenges, offering a multitude of benefits:

- Enhanced Equipment Lifespan: Filters remove abrasive and corrosive particles. Consequently, they protect pumps, valves, membranes (critical for [Desalination](https://www.gapuraliqua solutions.com/) processes), and other sensitive components. This action extends their operational life.

- Improved Process Efficiency: Clean water ensures consistent process performance. This reduces variations in product quality and optimizes chemical usage in subsequent treatment stages.

- Reduced Operational Costs: Fewer breakdowns, lower maintenance requirements, and optimized energy consumption translate into significant savings. Furthermore, this includes reduced water consumption through more effective backwash cycles.

- Compliance with Regulations: Effective pre-filtration is crucial for meeting environmental discharge standards for wastewater treatment.

- Resource Conservation: By enabling water reuse and minimizing waste, efficient filters contribute to sustainable water management practices. This is a growing concern in Indonesia.

Introducing GLS Series Filter Technology: Simple, Economic, Proven

In facing the challenges of industrial water management, an efficient, durable, and easily maintained filtration system is crucial. The GLS2000, GLS3000, and GLS4000 series filters serve as reliable solutions. They embody the philosophy of “Simple – Economic – Proven,” combining modern technology with practical design. This design is proven in various application conditions. Consequently, these filters represent a significant leap forward in industrial water filtration within Indonesia.

How Do GLS Disc & Screen Filters Work?

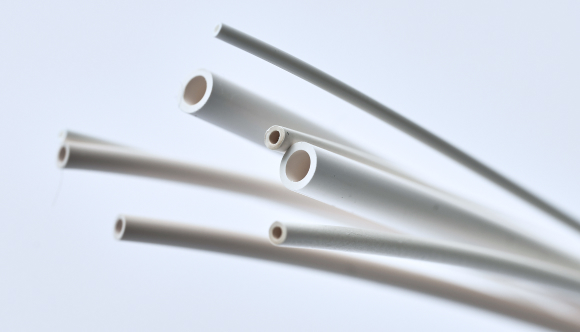

The core innovation of GLS filters lies in their automatic, disc and screen-based system. Unlike traditional filters that can quickly clog, GLS filters operate on a unique principle. This ensures continuous, effective filtration.

Swirling Flow Mechanism for Superior Filtration

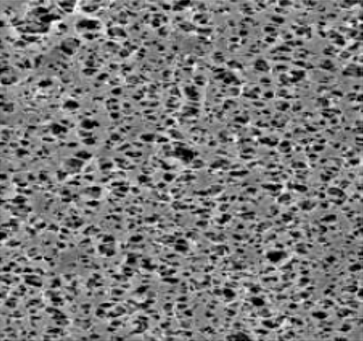

At the heart of the GLS system is a disc filter technology that utilizes specially designed discs or screens. As water enters the filter housing, it is directed into a swirling, centrifugal flow. This rotational motion causes larger particles to be flung outwards and settle. Meanwhile, smaller suspended solids become trapped by the intricate grooves of the stacked filter discs or the fine mesh of the screen. This filtration efficiency is remarkable, thereby ensuring a high quality of filtered water.

Advantages of Automatic Backwash Without External Intervention

One of the most significant advantages of the GLS Series is its self-cleaning capability. The system incorporates an automatic backwash filter mechanism. When the pressure differential across the filter indicates a buildup of trapped particles, the system automatically initiates a cleaning cycle. A portion of the filtered water is then reversed. This causes the filter discs to separate or the screen to flex, dislodging accumulated debris, which is subsequently flushed out.

Crucially, this entire process occurs automatically. There is no need for external tools, manual intervention, or interruption to the main filtration flow. This ensures continuous operation and minimal downtime. Consequently, this significantly contributes to a low maintenance filter solution. Furthermore, this mechanism keeps the filtration media clean longer. It also significantly reduces maintenance needs and backwash frequency.

Modular Design and Configuration Flexibility

The GLS Series boasts a highly adaptable modular design. This means individual filter units can be combined and configured. They can meet varying flow rates and capacity demands. Whether it is a small-scale industrial operation requiring a compact unit or a large wastewater treatment solutions plant needing extensive filtration capabilities, the modularity allows for easy scalability and integration. This flexibility, therefore, makes them an ideal choice for diverse needs across Indonesia’s industrial sectors.

Cost Efficiency and Long Service Life

Beyond their innovative filtration mechanism, GLS filters offer substantial economic benefits. Their operational cost reduction stems from several aspects:

- Reduced Water Consumption: The efficient backwash process uses minimal water. This contributes to overall water savings.

- Lower Energy Consumption: The design ensures low pressure drop. This minimizes the energy required for pumping.

- Durable Construction: These filters are made from corrosion-resistant materials. They are also designed to withstand extreme pressure and temperature variations. As a result, they promise an exceptionally long service life. This durability directly translates into fewer replacements and lower long-term capital expenditure. Hence, they are a true sustainable water management investment. Indeed, the economic aspect is a key advantage. In addition to saving energy and water in the backwash process, these filters are made from durable materials. These materials are resistant to extreme pressure and temperature, providing a long service life and lowering total operational costs.

Wide Applications of GLS Series Efficient Media Filters in Various Sectors

The proven performance and versatility of the GLS Series efficient media filter make it suitable for a vast array of applications across various industries in Indonesia. The GLS Series has been widely used in diverse applications. This ranges from irrigation systems requiring precise filtration to industrial processes demanding stable flow and high water quality. Consistent performance, operational efficiency, and ease of installation, therefore, make these filters a strategic choice in modern water management systems.

Filtration Solutions for the Paper and Pulp Industry

The paper and pulp industry requires vast quantities of clean water for various processes. These include pulp washing and paper machine showers. Suspended solids and fibers can quickly clog nozzles and damage equipment. GLS filters provide reliable pre-filtration, ensuring high-quality water output. This protects sensitive machinery and improves product consistency in paper industry water treatment.

Importance of Filtration in the Salt Industry

In the salt industry, particularly in brining and crystallization processes, particulate matter can affect the purity and quality of the final salt product. Salt industry water purification relies on efficient filtration. This removes insoluble impurities from brine solutions, leading to higher-grade salt and more efficient processing.

Vital Role in Wastewater Treatment

Before discharge or further treatment, wastewater often contains high levels of suspended solids. GLS filters serve as an effective primary or secondary filtration step in wastewater treatment solutions. This reduces the load on subsequent treatment stages, such as membrane filtration or biological processes. Thus, it improves overall plant efficiency and compliance.

Water Filtration for the Oil and Gas Sector

Water is extensively used in the oil and gas industry. Its uses range from drilling and fracking to produced water treatment and refining. Impurities in water can cause significant issues like reservoir damage, equipment fouling, and pipeline corrosion.

Oil and gas water filtration with GLS filters ensures the removal of solids. This action protects injection wells and optimizes various water-intensive processes.

Application in Irrigation and Modern Agriculture

While industrial in focus, it’s worth noting the GLS series’ roots in applications requiring precise filtration, such as modern irrigation systems. This highlights their ability to handle high flow rates while maintaining exceptional filtration efficiency. Such capability is crucial for industrial counterparts.

Process Water Treatment and Other Special Systems

Beyond specific industries, GLS filters are invaluable for general process water treatment. This applies across manufacturing, food and beverage, chemicals, and textiles. Any system requiring the removal of suspended solids to protect downstream equipment, ensure product integrity, or facilitate water reuse can benefit from this reliable water solutions technology. Furthermore, this includes pre-filtration for advanced systems like Reverse Osmosis (RO) in desalination technology, where membrane protection is paramount.

Choosing the Right Efficient Media Filter System for Your Needs

Selecting the ideal efficient media filter system requires careful consideration of several factors. This ensures optimal performance and return on investment.

Factors to Consider

- Flow Rate Requirements: Match the filter’s capacity to your process’s required flow rate. Conveniently, the modularity of GLS filters allows for flexible sizing.

- Water Quality (Inlet): Understand the type and concentration of suspended solids, organic matter, and other impurities in your source water.

- Desired Water Quality (Outlet): Determine the required particle size removal and purity level for your specific application.

- Operating Pressure and Temperature: Ensure the filter’s material and design can withstand your system’s operational parameters.

- Space Availability: Consider the physical footprint of the filter system.

- Maintenance Philosophy: If low maintenance and automated operation are priorities, systems like the GLS Series are ideal.

GLS Series as a Long-Term Investment

Choosing the GLS Series means more than just purchasing a piece of equipment. It is, rather, an investment in efficiency, longevity, and sustainability. Its “Simple – Economic – Proven” philosophy directly translates into:

- Simplified Operations: Automated cleaning reduces the need for skilled labor and constant monitoring.

- Economic Benefits: A long lifespan, reduced water/energy consumption, and lower maintenance save significant operational costs.

- Proven Reliability: Extensive use across various industries demonstrates its consistent performance under challenging conditions.

The Future of Water Management with Innovative Filtration Technology

As Indonesia continues its journey of industrialization and urbanization, the demand for clean water will only escalate. Innovative filtration technologies like the GLS Series are crucial for ensuring a sustainable water future.

Commitment to Environmental Sustainability

By enabling efficient water reuse, minimizing waste, and reducing the environmental footprint of industrial operations, GLS filters contribute directly to sustainable water management. This aligns perfectly with Indonesia’s growing commitment to environmental protection and resource conservation.

Expert Support and Services in Indonesia

For industries in Indonesia, having access to local expertise and support for water treatment solutions is vital. Companies like Gapura Liqua Solutions offer not only advanced filtration Products but also comprehensive technical assistance, installation services, and ongoing maintenance support. For any inquiries or to discuss specific project requirements, please feel free to Contact Us or connect with us on Our Social Media.

Conclusion: Efficient Media Filter – The Foundation of Clean Water for Industrial Progress

In conclusion, an efficient media filter is indispensable for any industrial operation striving for optimal performance, cost-effectiveness, and environmental responsibility in Indonesia. The GLS Series, with its innovative disc and screen technology, automated self-cleaning, modular design, and robust construction, stands out as a superior solution.

It is more than just a filtering tool; it’s a strategic asset. This asset safeguards equipment, enhances product quality, reduces operational expenses, and significantly contributes to sustainable water management and the reliability of water distribution systems. For Indonesian industries seeking to future-proof their operations and ensure a consistent supply of high-quality water, investing in a proven and efficient filtration system like the GLS Series is a clear path to long-term success.