CR Pump

The CR pump can handle different liquids such as potable water, chemicals, and others for various applications. It suits many pumping systems that need specific material and performance from the pump. The pump has two main parts: the motor and the pump unit. The motor meets EN standards. The pump unit has a sleeve, a pump head, various connections, and optimized hydraulics. The CR pump has different materials based on the liquid.

The CR and CRE pumps have several vertical stages and need priming. The pumps have either a standard motor (CR pumps) or a frequency-adjusting motor (CRE pumps). The pump has a pump head and a base. The pump head and the base hold the sleeve and the chamber stack with staybolts. The suction and discharge ports of the base are in line. All pumps have a mechanical shaft seal that is cartridge-type and maintenance-free.

Pumping liquids that are thicker or denser than water will lower the pressure, the power usage, and the hydraulic efficiency. The pump requires a bigger motor in these situations. If you have any doubts, contact GLS.

Water supply

- Filtration and transfer at waterworks

- Distribution from waterworks

- Pressure boosting in mains

- Pressure-boosting in high-rise buildings, hotels, etc.

- Pressure-boosting for industrial water supply

Pressure boosting

- Process-water systems

- Washing and cleaning systems

- Vehicle-washing tunnels

- Fire-fighting systems

Liquid transfer

- Cooling and air-conditioning systems (refrigerants)

- Boiler-feed and condensate systems

- Machine tools (cooling lubricants)

- Aquafarming*

Special transfer duties

- Oils and alcohols

- Glycol and coolants

Water treatment

- Separators

Irrigation

- Field irrigation (flooding)

- Sprinkler irrigation

- Drip-feed irrigation

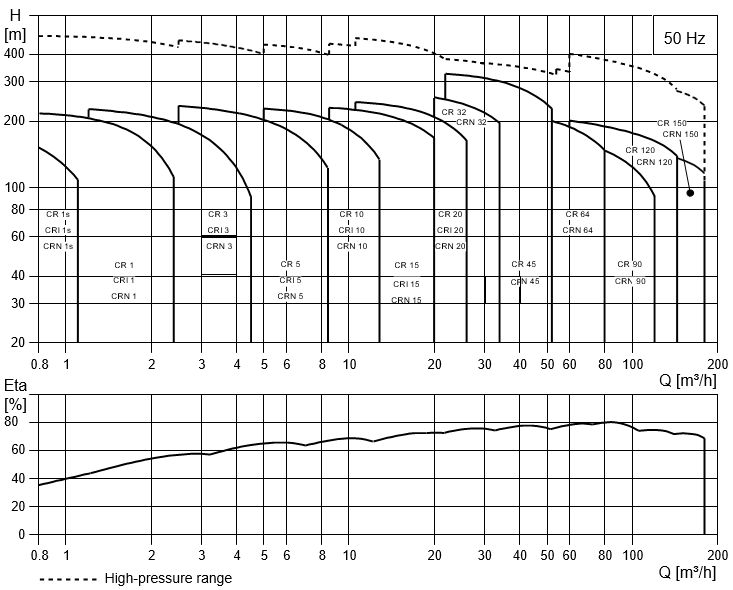

CR Pump Performance Range

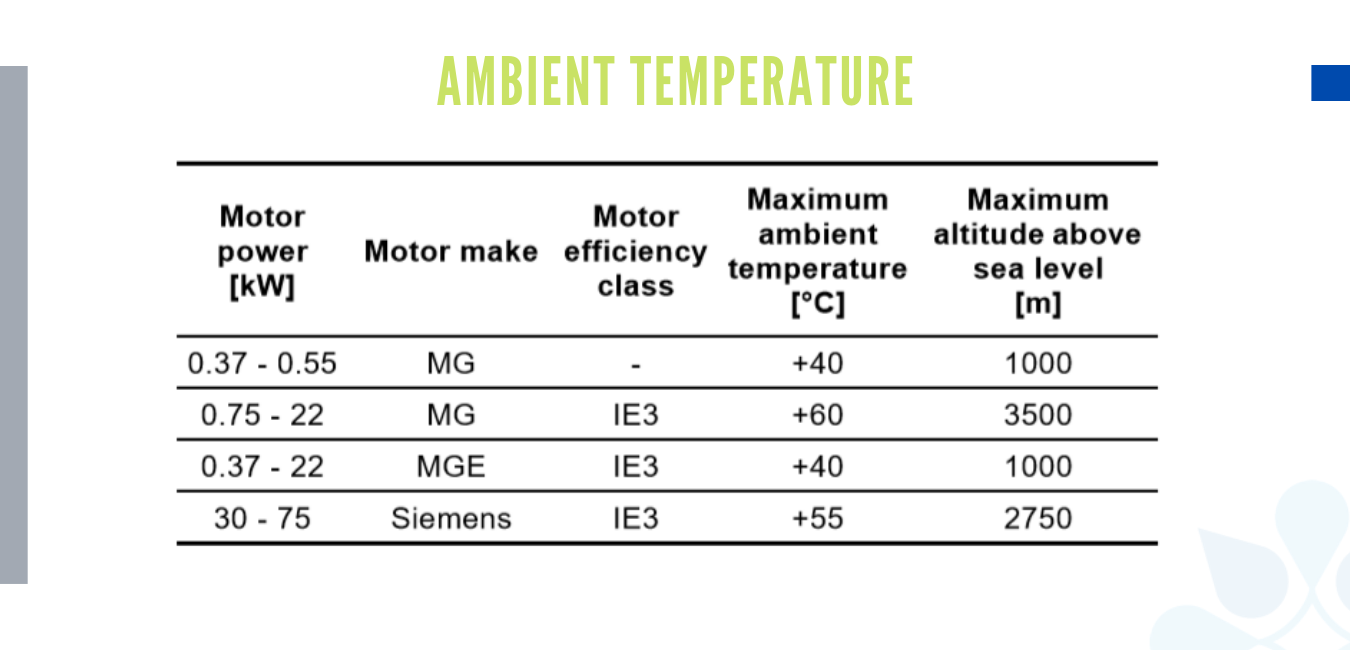

A totally enclosed, fan-cooled, 2-pole Grundfos standard motor with principal dimensions to EN standards fits the CR pump. The CR pump follows EN 60034 electrical tolerances. Moreover, the CR pump has three-phase MG motors as standard. Additionally, single-phase motors (1 x 220-230/240 V) are also an option for CR pump from 0.37 to 2.2 kW.

Get CR Pump From PT GLS

PT Gapura Liqua Solutions reflect our commitment to control the product quality by working closely with our strategic business partners, mostly leading components manufacturing firms in the field of water treatment, waste water treatment, desalination, and resources recovery.

You will guarantee product originality, advisory for your water system, and taking care by our skilled engineer to meet your business goals. Contact us now!