Sludge Dewatering Unit Design vs. Traditional Disposal Methods

Introduction

Sludge dewatering unit design is transforming how industries handle wastewater. Traditional disposal methods like drying beds, lagoons, and landfilling often cause inefficiencies and higher costs. With increasing environmental regulations, modern sludge dewatering systems present a sustainable and cost-effective solution. This article compares advanced dewatering units with conventional sludge treatment methods, focusing on cost, performance, and sustainability.

What Is Sludge Dewatering Unit Design in Wastewater Treatment?

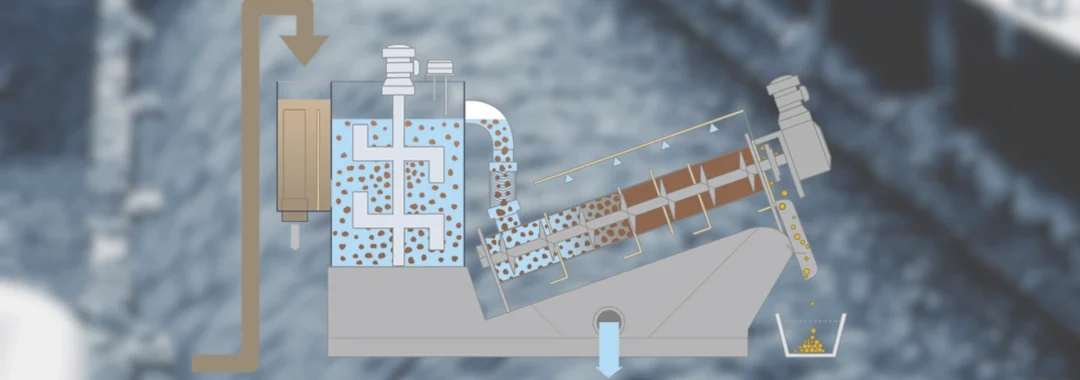

Sludge treatment design reduces water content in sludge, lowering disposal costs and environmental impact.

Key Features of Modern Sludge Dewatering Systems

- Capacity & Throughput: Handles continuous sludge flows efficiently.

- Automation & Controls: Reduces manual labor through smart systems.

- Polymer Dosing Optimization: Improves sludge cake dryness.

- Energy-Efficient Motors: Cuts operational power use.

👉 Many plants enhance separation with industrial decant tank applications for better wastewater sludge management.

Traditional Sludge Disposal Methods in Comparison

Traditional methods were once common, but they now struggle with compliance and efficiency.

Drying Beds for Sludge Treatment

Simple and low-cost but land-intensive and weather-dependent.

Sludge Lagoons as Disposal Units

Cheap upfront but cause odor, contamination risks, and high land use.

Landfilling Wastewater Sludge

Convenient but expensive due to hauling fees, landfill restrictions, and tipping costs.

Cost Benefits of Sludge Dewatering Systems vs. Traditional Disposal

Disposal Savings with Dewatering Equipment

Sludge dewatering reduces volume by up to 80%, cutting landfill and hauling expenses.

Labor and Maintenance Comparison

- Traditional disposal methods: labor-heavy and inefficient.

- Dewatering equipment: automated, consistent, and requires less manpower.

ROI from Sludge Treatment Design

Modern sludge management technology often pays back within 2–3 years, as seen in the GLS desalination project.

Performance of Sludge Dewatering Systems vs. Traditional Methods

Sludge Cake Quality

- Dewatering units: 20–35% dry solids.

- Traditional lagoons/beds: only 5–10% dry solids.

Disposal Efficiency in Sludge Management

Advanced wastewater sludge dewatering designs guarantee consistent output. Learn more via Hiller sludge dewatering resource.

Environmental and Regulatory Impact of Sludge Dewatering Design

Sustainability Benefits of Dewatering Systems

- Less transport emissions.

- Smaller footprint vs. traditional sludge disposal.

- Better alignment with strict wastewater treatment regulations.

Challenges of Traditional Sludge Methods

Lagoons and drying beds often fail compliance, cause leachate issues, and occupy large land areas.

Case Study: Sludge Dewatering in Food & Packaging Wastewater

A packaging facility replaced lagoons with sludge dewatering equipment and achieved:

- 50% disposal cost reduction.

- Higher sludge cake quality.

- Lower hauling frequency, reducing CO₂ emissions.

Future Trends in Sludge Dewatering and Treatment Design

Smart Monitoring and Automation

Sensors optimize polymer dosing and monitor cake dryness.

Compact Modular Sludge Management Units

Ideal for industries with space constraints.

Energy Recovery and Sustainability

Dewatered sludge can be repurposed for biogas production.

Stay updated with trends on Instagram, Facebook, and LinkedIn.

FAQ on Sludge Dewatering vs. Traditional Disposal

1. Why is sludge dewatering more efficient than traditional disposal methods?

It reduces sludge volume and weight, cutting disposal costs.

2. What sludge cake quality can be expected?

20–35% solids with dewatering vs. only 5–10% using lagoons.

3. Is dewatering suitable for small industries?

Yes, modular sludge management units are available.

4. How fast is ROI on sludge dewatering systems?

Typically 2–3 years.

5. Can sludge dewatering fully replace traditional disposal?

Yes, in most industries, though hybrid systems may be optimal.

Conclusion

The evidence is clear: sludge dewatering unit design delivers cost savings, improved sludge cake quality, and sustainability advantages over traditional disposal methods. For industries aiming to reduce sludge treatment cost and meet regulatory standards, modern dewatering systems provide a reliable and future-ready solution.

👉 Learn more on our sludge dewatering unit product page and explore advanced chemical solutions like best RO membrane antiscalant to protect your system.