Explore Our Industrial Mixing Tanks for Sale and Customizable Designs

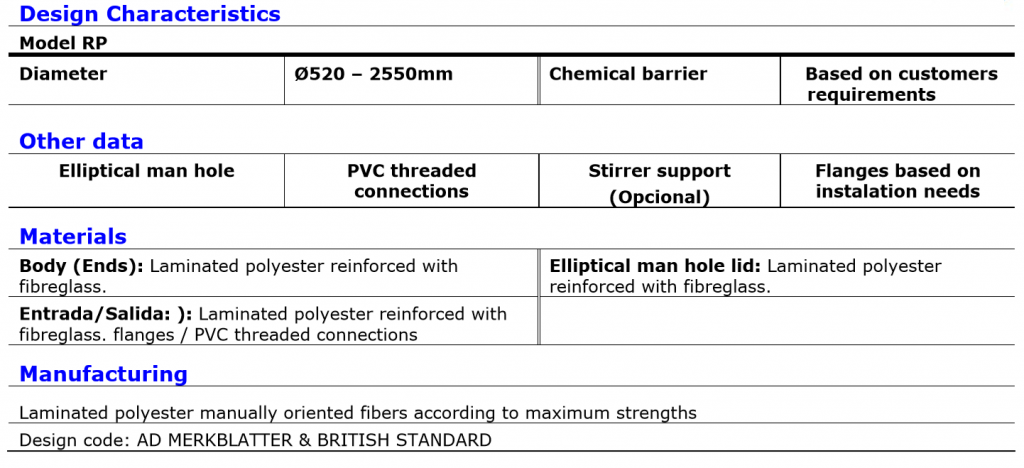

At our facility, we offer industrial mixing tanks available for purchase, and we go the extra mile by customizing designs to meet your specific requirements. These tanks are constructed using laminated polyester reinforced with fiberglass (GRP), ensuring durability and reliability. Additionally, we provide various chemical barriers tailored to handle different fluids, including NaOH, HCl, and H2SO4. Whether you need a standard solution or a customized design, we’ve got you covered!

Mixing Tank Feature

- Body: We reinforce the laminated polyester with fiberglass (GRP).

- Connection: We cast the flanges from polyester or use PVC connections.

- Overflow Device: The overflow device also consists of laminated polyester reinforced with fiberglass (GRP).

- Support: To prevent corrosion, we offer various chemical barriers.

Selecting the optimal mixing tank for water treatment is crucial for achieving efficient and effective results. Here are some guidelines to consider:

- Liquid Level to Tank Diameter Ratio:

- For most mixing applications, aim for an ideal liquid level to tank diameter ratio of 0.8. However, any ratio close to 1-to-1 is sufficient.

- A ratio that is too small won’t allow proper axial mixing in the tank. Avoid ratios less than 0.6.

- When the ratio exceeds 1.4, consider using dual impellers.

- If the ratio exceeds 2.0, re-evaluate tank selection, as slim tanks are less cost-effective for mixing.

- Longer mixer shafts increase the price of the mixer significantly1.

- Vertical Cylindrical Tanks:

- These are the most common type of tanks.

- Ensure they are either baffled or offset-mounted to prevent swirling.

- Baffles are not necessary for smaller tanks (<5,000 gallons or <10’ height), but for larger tanks, baffles are cost-effective compared to heavy-duty offset-mounted mixers.

- Rectangular Tanks:

- Calculate the equivalent diameter by taking the square root of Length x Width and multiplying it by 1.13.

- Similar to cylindrical tanks, maintain a liquid level to equivalent tank diameter ratio of 0.8.

- Rectangular tanks are effective for blending (self-baffling) but not recommended for solid suspension due to corner “dead spots” where solids accumulate

Get Mixing Tank From PT GLS

PT Gapura Liqua Solutions reflect our commitment to control the product quality by working closely with our strategic business partners, mostly leading components manufacturing firms in the field of water treatment, waste water treatment, desalination, and resources recovery.

You will guarantee product originality, advisory for your water system, and taking care by our skilled engineer to meet your business goals. Contact us now!