Special Air Diffuser

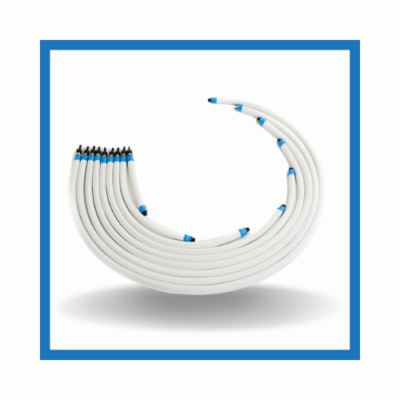

Special air diffuser is a semi flexible, high-efficiency fine bubble air diffuser with quick and easy installation for water reservoir.

Special Air Diffusers

Depending on the amount of air, oxygen or carbon dioxide needed, you can choose from 9 different lengths of this special air diffusers. This device is semi-flexible and highly efficient at producing fine bubbles. As a result, it can achieve oxygen transfer rates of up to 5kg/kw, 10m3/h of air and 1 k9 of O2/h. Moreover, this air diffuser is easy to set up and maintain, even when the air blowers are running and the water reservoir is full.

Why Use Special Air Diffuser?

Carbonate and iron deposition block solid diffusers, making them hard to clean and maintain. On the other hand, flexible membrane diffusers resist fouling better, but they have some drawbacks. They require a heavy frame or anchoring to the aeration tank’s base, which limits their use in lagoons or retrofitting systems.

Because its semi flexible air diffuser, carbonates and metal oxides simply crack off the unit. Also because our diffuser has its own internal ballast it does not need to be anchored to the base of the tank. If any cleaning or maintenance is required, the diffuser is simple pulled out of the rank using the 1/2″ air delivery hose. The tank can be full of water and the air blowers running when the dussuser is removed.

Feasible Application Approach

Get Special Air Diffuser From PT GLS

PT Gapura Liqua Solutions reflect our commitment to control the product quality by working closely with our strategic business partners, mostly leading components manufacturing firms in the field of water treatment, waste water treatment, desalination, and resources recovery.

You will guarantee product originality, advisory for your water system, and taking care by our skilled engineer to meet your business goals. Contact us now!