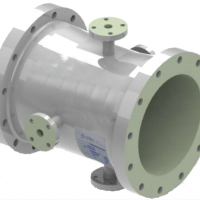

FRP STATIC MIXER

The FRP Static Mixer design aims to mix additives quickly. It consists of a FRP ring with FRP static nozzles. The homogeneity of the mixture does not depend on the additive percentages. The equipment is easy to assemble and install. It connects to the piping system through flanges.

FRP Static Mixer Construction Material

Fiberglass Reinforced Polyester (FRP) is the best material for corrosion and high flows. Male molds make the main cylinder of the Static Mixer, using the manual applying process (hand layup) and the filament winding technique. This gives FRP an internal surface with low friction and pressure drop. The internal nozzles, also made of FRP, are integral to the body. Suitable coatings protect the injection ports for the most critical chemicals.

Design

Standard and customized design codes upon request (EU and US codes)

Painting and Finishing

Internal:

– Chemical barrier of vinyl-ester resin

– Natural finishing without treatment due to filter housing’s design

External:

– Priming with a two-compound painting with the proper adherence for FRP

– Final painting with a two-compound painting

Get FRP Static Mixer From PT GLS

PT Gapura Liqua Solutions reflect our commitment to control the product quality by working closely with our strategic business partners, mostly leading components manufacturing firms in the field of water treatment, waste water treatment, desalination, and resources recovery.

You will guarantee product originality, advisory for your water system, and taking care by our skilled engineer to meet your business goals. Contact us now!